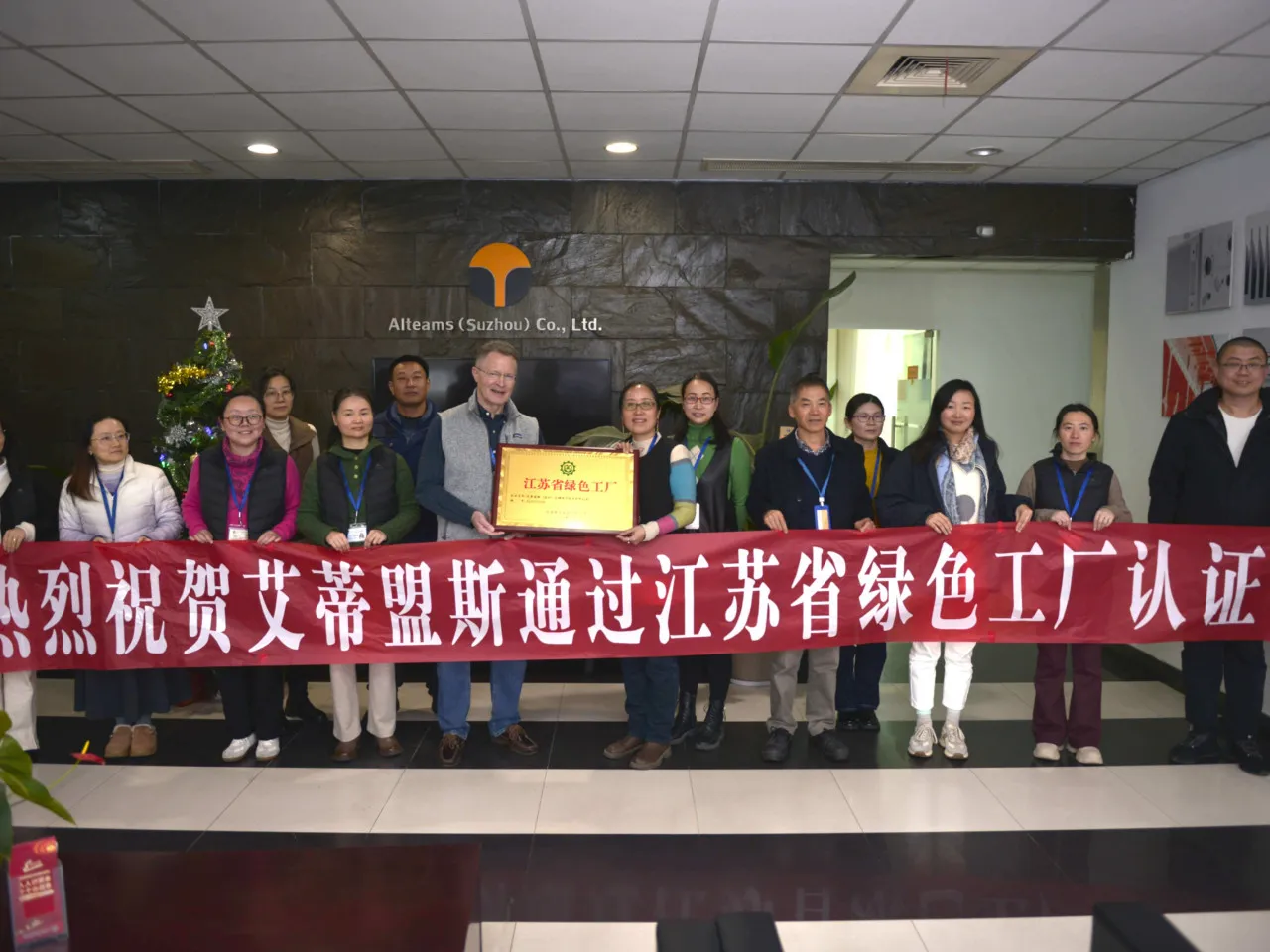

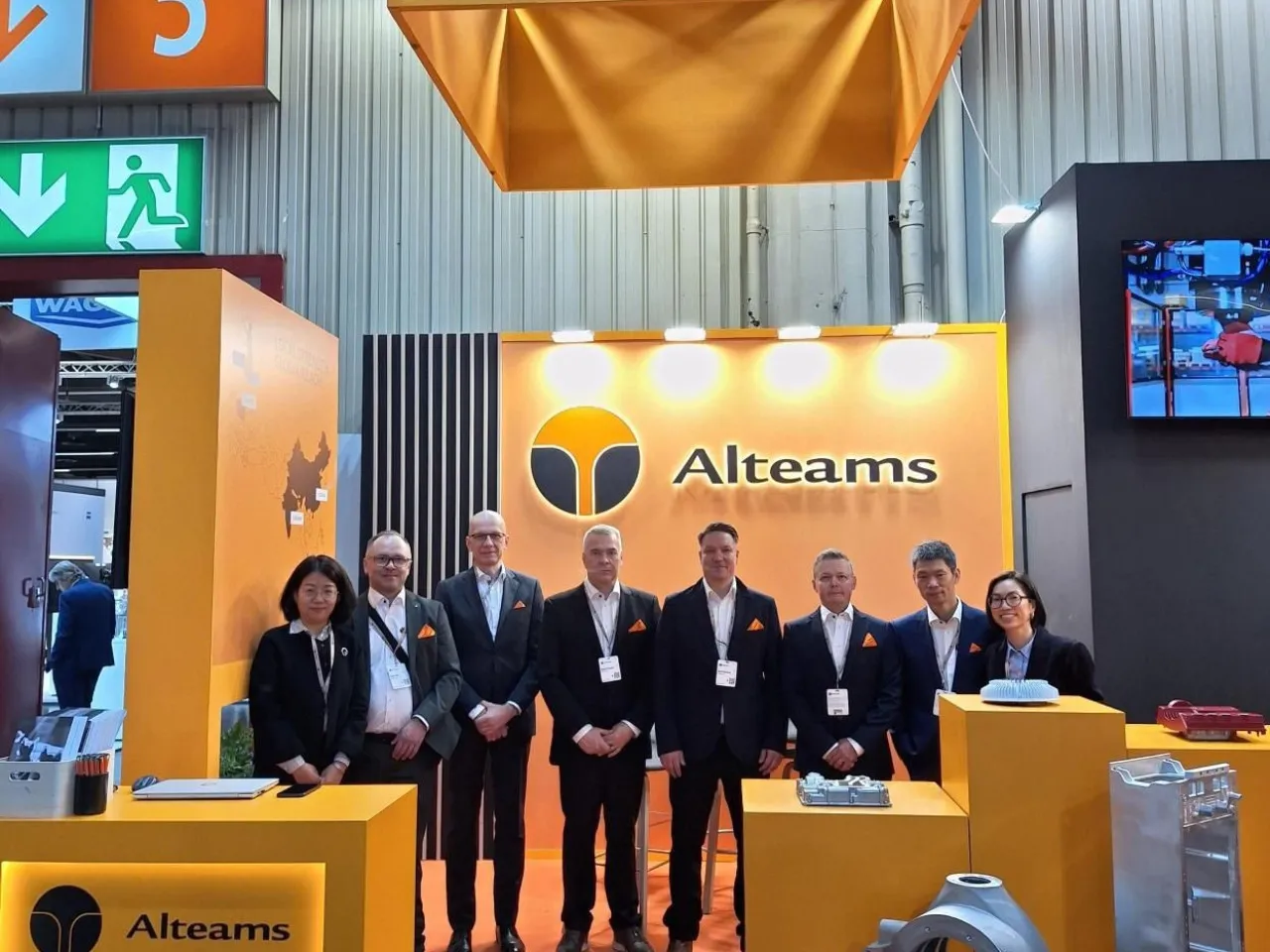

Euroguss - Kicking Off 2026 with Inspiration and Connections!

We are pleased to reflect on a successful start to 2026, with three days of engaging discussions and meaningful networking opportunities at Euroguss 2026. Thank you to everyone who visited our stand — it was a pleasure connecting with you.