Season's Greetings

With the holiday season upon us, we would like to extend a warm thank you to all of our customers and partners for your collaboration throughout the year.

See you at EUROGUSS 13 -15.01.2026 in Nuremberg, Germany!

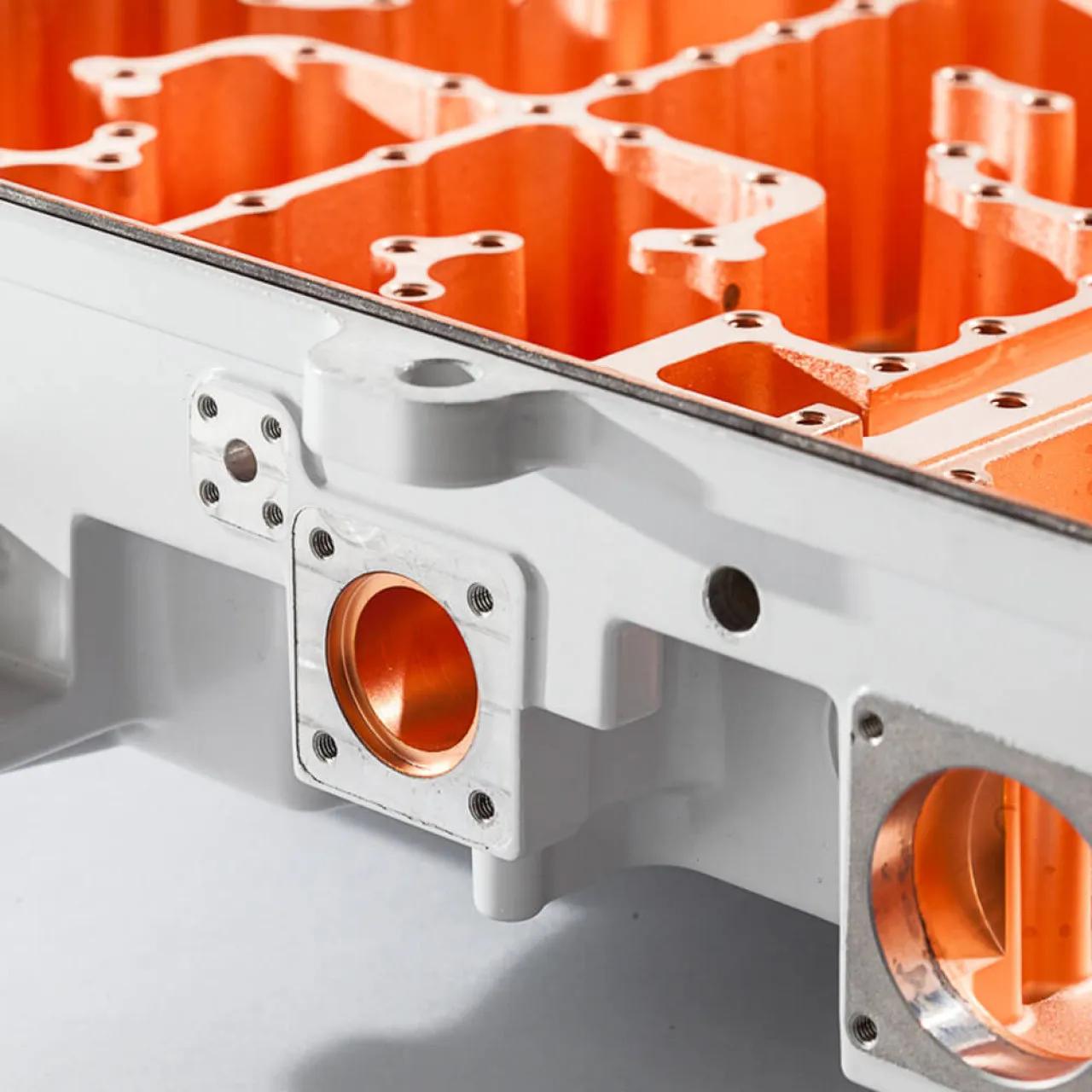

Over 80 years of expertise delivering high-quality aluminium castings worldwide. Five global sites. Tailored solutions at every scale, combining quality, sustainability and reliability.

Our capabilities include:

At Alteams, we combine engineering expertise with innovative solutions to ensure your projects succeed.

Our skilled team delivers custom engineering support and process optimization that maximize efficiency and performance.

Alteams leads in sustainable aluminium casting solution, delivering high quality, environmentally responsible services through efficient manufacturing practices.

With the holiday season upon us, we would like to extend a warm thank you to all of our customers and partners for your collaboration throughout the year.

We’re excited to share our 2025 EcoVadis assessment results. This year our score jumped from 67 to 76, placing us in the top 7% of our industry (93rd percentile). This improvement reflects significant progress in social responsibility, alongside continuous work in other sustainability areas.

We’re excited to announce that Alteams will be attending EUROGUSS 2026, the leading international trade fair for the die casting industry, happening on 13th – 15th January in Nuremberg, Germany!